Implementing Lean programs in job shops and made-to-order environments can be challenging. Learn some of the key attributes unique to job shops, and how to begin down the path of continuous improvement.

Learn the 8 wastes of lean and how they are applicable to a job shop.

How many hours do your workers actually earn in an 8 hour shift? Find out the true cost of your meetings

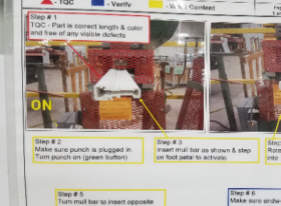

Standard Work can be a powerful tool in a job shops to improve the efficiency, create consistency between operators, and keep processes in control.

Make more profit by increasing throughput, decreasing inventory, and reducing overhead - apply the Theory of Constraints to your job shop.

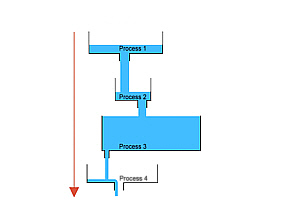

There is only one true measure of improvement in a plant: how much more throughput is produced, while reducing inventory and expenses. And the best way to improve your throughput is by focusing on your bottlenecks and constraints.

Lead time constraints are unique to job shops and are created by the chaotic routings and process times present. They are often hidden from view by our product mix, and show up as late deliveries to customers.

Focusing on your lean implementation efforts on constraints will deliver results, while also building a lean culture through success.

Single Minute Exchange of Dies should be an integral part of your shop's plan to improve efficiency and lean out your operation.

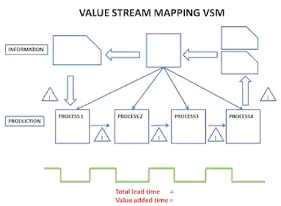

Value stream mapping is a lean tool that is often ignored in most job shops because of it's severe limitations, but it can provide useful data if we use learn when and where to apply it.

Stop simply "going thru the motions" on your gemba walks, get buy-in from all stakeholders, and learn alternative methods of building value for your organization

Compare and contrast Kaizen events to the Operational Excellence events.

The Toyota Production System is the best system in the world - for manufacturing Toyota cars. Job Shops need to be innovators and create new tools to solve their unique problems.